Finally, the integrated Intelligent Display Module allows users to perform standard maintenance functions without the need for a separate computer running programming software and creates a bridge that integrates the control system with the Industrial Internet. Fourth, since it is based on standard Intel architecture, GE can deliver control solutions with unique capabilities such as very large memory sizes and on-board storage capability. Third, the ability to deploy the RXi architecture using both control and IPC modules interconnected provides a compact, high performance solution for applications requiring visualization, data archiving, or other advanced computational tasks at the point of control. With open standard PROFINET as the I/O network, users are free to choose best of breed I/O and other devices, like drives and vision systems, for use in their systems. Second, it has built-in PROFINET with ring redundancy to provide a simple to use, low installation cost, high performance redundant I/O network. First, it has no local I/O which creates the basis for future upgradeability. To provide the performance sophisticated control applications need today, the core of the product family is a COM Express architecture with multi-core CPUs, which will allow GE to offer a range of products that will be continually refreshed without impacting the user’s application.įrom a design perspective, the RXi controller is a departure from traditional systems. The RXi platform builds on GE’s deep expertise in the design of embedded control platforms as well as industry-standard open architecture technologies that deliver what companies in today’s economy need –- improved performance, integration into the Industrial Internet, and greater uptime and low total cost of ownership (TCO). The RXi platform fully supports GE’s cloud-based collaborative automation platform development and deployment paradigm.īased on leading-edge computing and network technology, and supported by an emerging ecosystem of cloud-based support tools, the RXi will help customers gain productivity benefits from machine-to-machine connections and the skill sets of a digital native workforce. This facilitates better real time control of operations and improved integration into plant-wide and enterprise systems.

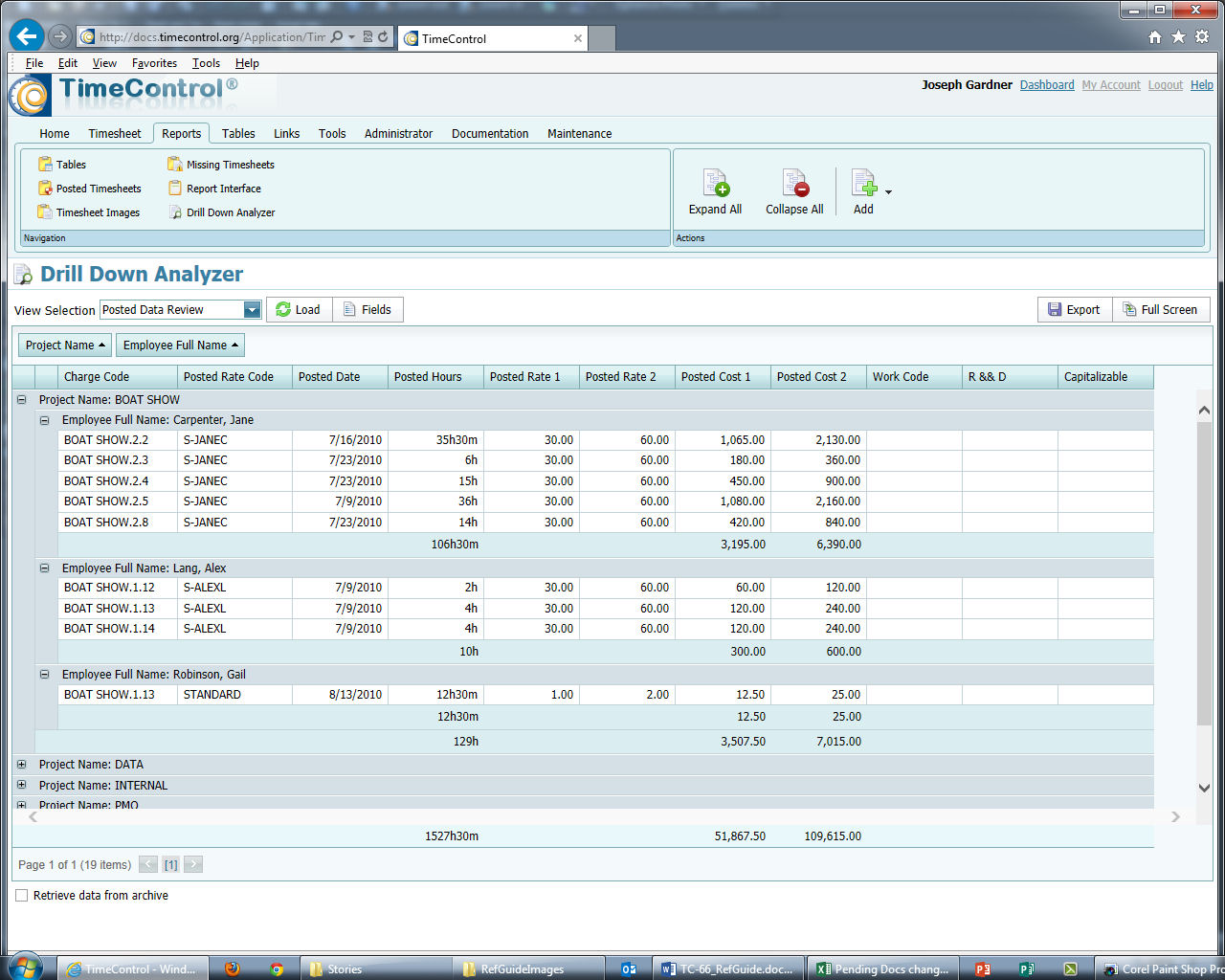

GE TIMECONTROL PC

RXi Industrial PC (IPC) configurations are able to run HMI, Historian and analytics applications right at the machine, even in harsh environments. The PACSystems RXi family of controllers has built-in redundant PROFINET interfaces, delivering high performance, high uptime control solutions. These high performance features are coupled with GE’s PACSystems control engine to deliver uncompromised performance and application flexibility.

GE TIMECONTROL FULL

The RXi platform offers a full complement of high speed interfaces, with multiple gigabit Ethernet and USB 3.0 ports. JGE Intelligent Platforms announced PACSystems RXi, a control and computing platform designed for the needs of the Industrial Internet. GE Intelligent Platforms announces PACSystems RXi

0 kommentar(er)

0 kommentar(er)